Snowmaking 101

How does snowmaking work?

The snowmaking process produces real snow from water when atmospheric conditions are right. It is critical to the operation of many ski areas around the world today. In the absence of natural snowfall, snowmaking allows ski areas to remain open and provide a quality snow surface for guests to enjoy.

While commercial snowmaking systems operated at ski areas produce large amounts of snow, small snowmaking systems can be built for home use. This guide aims to be an introduction to the process of making real snow, the different types of snow guns, and includes information about how you can start making snow at home.

For more in-depth information about the physics behind snowmaking, be sure to check out our snowmaking science page!

The Ingredients

What do you need to make snow? The basic ingredients for snowmaking are:

- Cold weather. A quantity called the wet bulb temperature must be below 28°F in order to make snow.

- Compressed air. As the compressed air is released into the atmosphere, the expansion results in a cooling effect that is important for nucleation.

- Pressurized water. The high-pressure water is sprayed through nozzles that ensure proper droplet size.

- A snow gun. This is the apparatus that releases the pressurized air and water in the into the air, producing water droplets that freeze to form ice.

When all of these ingredients are present, snowmaking should be successful! The amount of snow produced depends on factors such as amount of water used, temperature, and the type of snow gun, which we will discuss in more detail below.

Weather

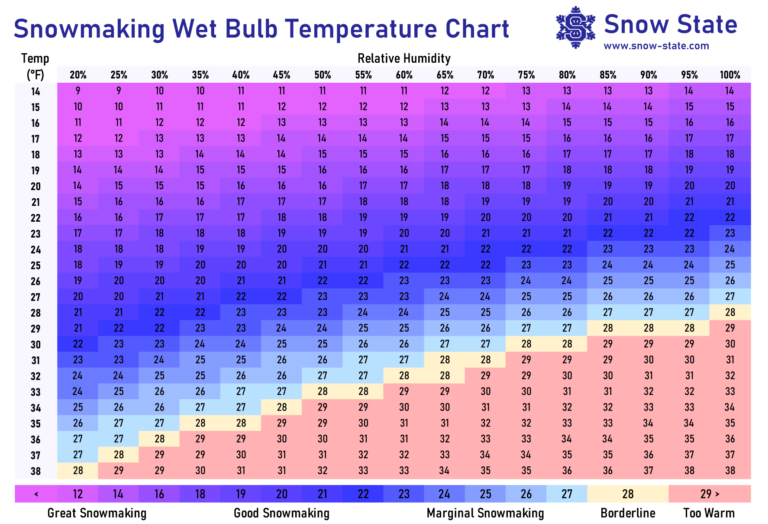

Weather is the most critical part of the snowmaking process; if it is too warm, the process will fail to produce snow. To make snow, the wet bulb temperature, which takes into account temperature and relative humidity, must be below 28°F. This allows the water droplets to freeze in the air before falling to the ground as snow.

The “wet bulb cooling” process, also known as evaporative cooling, means temperatures are lowered by water evaporating into the air. The lower the relative humidity, the greater this cooling effect will be. This process is useful for snowmaking, as the cooling of water droplets is aided by evaporation.

From the snowmaking wet bulb temperature chart, you can see that snowmaking is theoretically possible even when the temperature is above freezing, if the relative humidity is low enough.

Slushy snow may be made with properly designed equipment in “borderline” conditions, but most snowmaking equipment performs well in the lower 20s and below. While snow quality may be wet at higher temperatures, dry and powdery snow can be produced with wet bulb temperatures in the teens.

You can use the wet bulb temperature chart with the current temperature and relative humidity to see if snowmaking is possible at your home! We recommend purchasing a reliable weather station to measure conditions in your backyard, as local variations in temperature and humidity can have a big impact on snowmaking conditions.

Air and Water

Most snow guns require a supply of air and water under pressure to produce snow. Commercial snowmaking systems use industrial air compressors and water pumps to move the large quantities of air and water necessary to cover an entire mountain with snow. On the home scale, an ordinary air compressor and a pressure washer can be used to supply these ingredients.

Air Supply

Snowmaking uses air compressors to provide the compressed air required for nucleation. The expanding compressed air (typically 70-120 psi) cools rapidly as it leaves the snow gun, and when mixed with a small amount of water, produces small ice crystals. These crystals serve as a “seed” to form ice crystals from larger water droplets (supplied by the water pump) that will fall to the ground as snow. You can learn more about the nucleation process by visiting our snowmaking science page.

Air compressors of various sizes can be used to make snow at home, but some small pancake-type compressors may be too small for snowmaking. To determine if an air compressor will deliver enough air, we must know the air flow rate, measured in cubic feet per minute (abbreviated cfm or scfm).

For most home snowmaking systems, an air compressor should be rated for at least 4 cfm @ 90 psi. Snow State’s snow guns are able to produce snow with as little as 2 cfm @ 90 psi, allowing for substantial energy savings.

Typically, more air is better, particularly at marginal temperatures. More air flow produces a greater cooling effect and better nucleation in these conditions. At lower temperatures, however, expect diminishing returns.

What air compressors are best? Historically, home snowmakers have advised against oil-free compressors. However, through years of testing, we have not found any issues with using oil-free compressors. Due to the cold outdoor environment, the compressors will not get too hot from running continuously. In recent years, “ultra-quiet” air compressors have emerged, which have proven themselves as a great alternative to other loud oil-free units. We have tested California Air Tools and Fortress units with great success in home snowmaking applications.

Water Supply

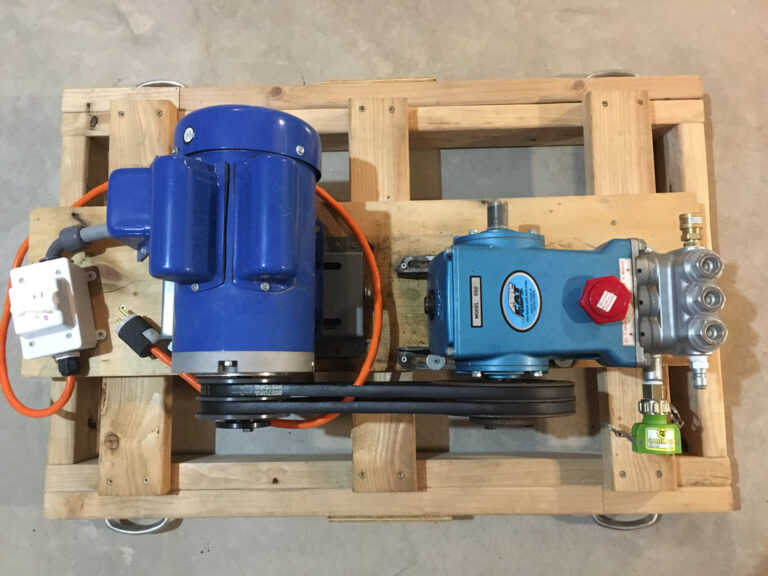

A high-pressure water pump is necessary to provide the water for snowmaking. The water must be under high pressure (typically 400-1000 psi) so it breaks up into small droplets upon exiting the snow gun, which can freeze before reaching the ground.

An electric pressure washer is a good low-cost solution for home snowmaking. When selecting a pressure washer, the important specification is the water flow rate in gallons per minute (abbreviated gpm). The snow production is determined by water flow; the more gallons per minute of water the pump delivers, the more snow will be produced.

Most electric pressure washers are rated for between 1.2 – 2.0 gpm, and will produce modest amounts of snow. The maximum pressure rating of the pressure washer is irrelevant, since that number is always much above the pressures needed for snowmaking.

It is important to note that for all pump setups, the flow of water delivered by the pump is constant, with few exceptions. The water flow is determined by the pump’s rotation rate, and the pressure is determined by the selection of snowmaking nozzles. Thus, the proper selection of snowmaking nozzles is critical to the success of any snow gun.

For those who are a bit more serious about home snowmaking and want to boost their snow production, a more costly water pump setup can be built using a pump rated for high pressure. These pumps, typically used in the pressure washing and car wash industries, include brands such as Cat Pumps, General Pump, and AR, and can deliver water flow well over 3 gpm, depending on the pump and motor used. These pumps can be driven by electric and gas motors, and connected via direct drive or a belt and pulley system.

The advantages of using the belt/pulley method are that the flow of water can be adjusted based on the pulley selection (altering pump rpm), and motors that spin at different rates than the pump’s rated rpm can be used. However, the simplicity of direct drive pump setups may be preferable in many instances.

Snow Guns

Snow guns, sometimes referred to as snowmakers or snow machines, release the correct mixtures of air and water into the air in order to turn the water into snow. They are equipped with different types of nozzles that produce the proper spray patterns.

There are three general categories of snow guns:

- Air/water guns

- Stick/lance guns

- Fan guns

All snow guns require some mechanism for nucleation in order to seed the formation of ice crystals. As discussed previously, nucleation involves a very small amount of water mixing with compressed air. Each snow gun may be described by its nucleation method as either internal or external mix, based on how the water and air mix to form the nucleation stream.

In internal mix snow gun designs, air and water mix inside the snow gun. Most commercial snow guns as well as many simple home builds are internal mix. Internal mix designs generally result in a better atomization of the nucleation water and thus a better quality (more frozen) nucleation stream and snow production. However, on the home scale, it can be difficult to get this mix adjusted properly, as very small amounts of water are needed. Additionally, if the flow of air is stopped, water may back down the air line and cause problems.

Water and air mix outside of the snow gun in external mix designs. This eliminates the chance of water flowing back into the air line, and allows the operator to visually inspect the mixing of air and water. Misting nozzles are often used to control the water flow, eliminating the need for a valve to regulate water flow. However, external mix nucleators are often susceptible to wind interference and do not produce the same level of atomization as internal mix nucleators. Additionally, with the low flow rates and small orifice sizes required for home snowmaking, external mix designs often require heating elements to eliminate ice formation on the nozzles. This can be an additional hassle and expense.

Snow State’s internal mix nucleation manifold offers the best of both designs – superior atomization and freeze-up prevention offered by internal mix designs without the need for any adjustment. This allows our designs to use less compressed air than other home snowmakers, saving energy.

Air/Water Snow Guns

Air/water guns are the simplest type of snow gun and some of the most reliable snow guns on the market. These snow guns are of the internal mix variety, as separate air and water streams mix inside of the snow gun body, and this mixture usually exits through one large orifice. They are easy to build and operate, but come with several drawbacks.

The snow gun operates with a large amount of compressed air (typically near 100 psi) mixing with a small amount of water (similar pressure) inside the snow gun. The mixture is blasted out of the snow gun at high velocity, and the rapid decompression of the compressed air results in rapid cooling of the plume.

A distribution of water droplet sizes is generated in the plume, with some larger than others. Nucleation takes place when some of the smallest droplets freeze to form the ice nuclei that seed the ice formation from the larger droplets in the plume. Ice crystals then fall out of the plume as snow.

The primary disadvantage of air/water is energy consumption; they require a very large amount of compressed air to operate. Recall that we measure air flow in cfm (cubic feet per minute), and water flow in gallons per minute (gpm). Many commercial air/water guns operate with well over 200 cfm of air while using less than 20 gpm of water. We see that the air to water ratio (cfm to gpm) can be much greater than 10:1, sometimes nearing 40:1 with these designs in marginal temperatures. Snow guns with high air to water ratios such as air/water guns are considered high energy, as they use more energy to convert the water to snow due to the significant compressed air usage.

Despite increased energy usage, air/water guns do have some advantages which keep them in use today. The increased air flow allows these snow guns to perform better than other types of snow guns in marginal conditions, due to the cooling effect from decompression of the compressed air. Additionally, these air/water guns do not need high water pressure to operate; the water pressure just needs to be a bit higher than the air (~100 psi). This is a significant advantage at low-pressure locations on a mountain where other types of snow guns may struggle to make quality snow.

It’s easy to build a simple air/water type snowmaker at home. All you need is an air compressor, a water supply, and some pipe fittings. Head over to our free plans section to check out some designs, but be warned – a simple “tee gun” will not win any awards for snow production!

Stick/Lance Snow Guns

The most popular type of snow gun is the stick gun, also commonly called a lance gun (because of it’s shape) or a combo gun. This is the design most commonly used in home snowmaking. Stick guns may rely on either an internal or external nucleation method.

In this design, an assortment of vertically-aligned nozzles spraying water and air are embedded in the snow gun body, or connected via pipe fittings. Most of these nozzles, called the bulk water nozzles, spray high-pressure water in a flat fan pattern, creating a plume of small water droplets of similar size. At least one nucleation nozzle is required that sprays a mixture of compressed air and water.

This nozzle functions much like the air/water gun introduced above, as the cooling effect from the compressed air freezes the water in this mixture in a process called homogeneous nucleation. Many small ice crystals are produced, which act as “seeds” for forming larger ice crystals from the bulk water. The combination of an air/water nozzle and bulk water nozzles on stick guns is why they are sometimes referred to as “combo guns” in the home snowmaking community.

Often, especially in colder weather, these guns can operate with a 1:1 or smaller air to water ratio (cfm to gpm). This is because it does not take a lot of compressed air to create the nuclei needed to seed the bulk water droplets. While commercial air/water guns often mix upwards of 20 gallons per minute of water with the compressed air, stick guns use only a few gallons per hour in the nucleation mixture.

As a result, a lesser amount of compressed air is needed to cool this water enough to form ice nuclei. The bulk water droplets must be cooled to below-freezing temperatures by the ambient air alone, without the aid of compressed air. Therefore, stick guns may not perform as well as other types of snow guns in marginal conditions, and require adequate hang time for the water droplets to cool and freeze. This is accomplished by mounting stick guns on tall towers, occasionally in excess of 20′ in height.

Some stick guns, often called “water sticks”, operate without the need for compressed air or nucleation nozzles. They rely on self-nucleation of the snowmaking water at very low temperatures, typically operating at temperatures near or below 0°F/-18°C. Water sticks are highly economical, but only perform well in very cold climates.

While stick guns are the low-energy alternative to air/water guns, they do have some limitations. Due to the spray characteristics of the nozzles used, stick guns require significantly higher water pressure than air/water guns in order to ensure proper water droplet size. Since water droplet size is related directly to water pressure, low water pressure (typically under 350 psi) will create large droplets that may fail to freeze completely before reaching the ground. This is a larger issue in marginal conditions, where the freezing process is slower. While stick guns may not be suitable for every location in commercial applications, they are well-suited for home snowmaking.

It’s easy to build a small internal mix stick gun to make snow at home – all you’ll need is an air compressor, a pressure washer, and some pipe fittings. Depending on the temperature and your pressure washer’s rated flow, you can expect to make several feet of snow in just one night! To get started making your own snow, check out some of our snow guns, or take a look at our free plans for a great DIY home snowmaking project.

Fan Guns

Like stick guns, fan guns have separate bulk water and nucleation nozzles, and may rely on either internal or external nucleation methods. These nozzles function in the same manner as in stick guns, but the arrangement of the nozzles is quite different in a normal fan gun design.

A typical fan gun has a large fan mounted at the larger end of a slightly-tapered barrel. At the small end of the barrel, bulk water nozzles are mounted in one or more rings surrounding the barrel. These nozzles usually have lower flow rates than stick gun nozzles, and may have different spray characteristics. Nozzles with a hollow cone spray pattern are commonly used on fan guns.

The fan moves a large amount of air through the barrel, which propels the water droplets over a large distance. The increased hang time, as well as the ambient air inducted by the fan typically result in superior snow quality. As a result, properly-designed fan guns offer the best performance in marginal conditions of any type of snow gun, but come with added complexity.

Fan guns are quite efficient with respect to the air to water ratio – sometimes approaching 1:4. However, fan guns may not be considered low-energy snow guns due to the power draw from the large fan. Where the power is available, though, fan guns fit nicely with any existing snowmaking system. Due to the added hang time offered by the fan, they can operate with lower water pressures than stick guns, often as low as 100 psi. Additionally, many commercial fan guns are equipped with on-board air compressors, which reserves the snowmaking system’s compressed air capacity for other low-energy snow guns.

Fan guns can be built for home snowmaking applications, but these builds require more advanced fabrication skills than the combo gun mentioned above. Home fan gun builds can range in complexity from a ventilation fan mounted in a five-gallon bucket to industrial fans with custom metal barrels. Properly-designed home fan guns offer the advantage of superior snow quality, and can operate on lower water pressures than stick guns. They are most suitable for water flow rates greater than 5 gallons per minute. If you’re looking to build a fan gun yourself, the home snowmaking forum is a great place to look for inspiration!

Summary

Snowmaking is critically important to the operation of ski areas around the world today. Cold weather, compressed air, pressurized water, and a snow gun are the ingredients required to make snow, as these ingredients allow water droplets to be transformed into ice crystals in the outside air.

There are three general types of snow guns – air/water, stick/lance, and fan guns – each requiring a nucleation method to seed the formation of ice crystals. Nucleation requires a mixture of compressed air and water, and this can occur inside the snow gun body (internal mix) or outside the snow gun (external mix). While ski areas require large equipment to produce massive volumes of snow, you too can make snow using the same process in your own backyard. All you need to get started making snow is an air compressor, a pressure washer, and a snow gun!

We have the products and information necessary to help you make snow. Our snowmakers offer a turn-key solution to home snowmaking – just connect your air compressor and pressure washer to make snow! If you’re looking for a fun DIY project, our free plans and selection of snowmaking nozzles are a great place to start. Check out our new blog for tips and tricks about snowmaking that will improve your home snowmaking experience.

If you have any questions about snowmaking or just want to chat, don’t hesitate to contact us!